Sun 11 Nov 2012

The past month has just been a busy one at work; midterms are upon us, and everyone is realizing that it’s time to buckle down and get serious coming into the home stretch. It’s hard to believe that Rhinebeck was 3 weeks ago already, and it’s also hard to believe that it’s only been three weeks. It feels like an eternity, probably partly because I haven’t been knitting.

The festival was an almost-overwhelming glut of fiber, but since then there’s been hardly anything happening on the crafting front. Fun as it was, Rhinebeck weekend came between my two busiest weeks so far this semester (it was 80+ hours of work there for a couple of weeks), and it takes a lot of energy for me to be out and engaging at an event like that. No complaints about Rhinebeck, but I feel like I am just now beginning to repay some of the energy deficit I built up by not having downtime between those busy weeks.

One sure sign of energy (and time) returning is the return of crafting. I wasn’t quite ready to work on my current “big” spinning project (for Branden’s sweater), so I decided to try some of those batts that I carded up earlier this year.

This skein came from about 4 oz of blended batts, made of seconds from the dye studio. The base green is a corriedale, and the accents are BFL and polwarth, I believe. There’s also a tiny bit of banana viscose in there, just for fun.

This is the first batt I have ever spun, and I learned a few things doing it.

1) I like spinning from batts just fine. This is good to know, because I don’t like all of the fiber preps I’ve tried, and I wanted to make really sure that I would enjoy batts before making a final decision on the drum carder. I’d say they’re about equal to commercial top, in my opinion. Slightly less smooth to spin, but really nice and fluffy to make up for it. Definitely something I’d like to do again.

2) I expect batts to be very soft, and full of very fine, luxurious fibers. I did not know that I expected this. In fact, it kind of surprises me that I do. But when I looked at those batts and dreamed about the yarn they’d make, a practical corriedale sock yarn was not what came to mind. It took me a while to forgive the fiber for being coarser than my mind had imagined it, even though I knew full well that it was from a not-terribly-fine batch of corriedale. I’ve been thinking a lot about this expectation, and I think that part of the reason for it is the way that I blended the colors and the textures together. I made it look like an art batt, but it didn’t feel like an art batt, and I think that’s what lead to discontentment when I sat down to spin. I plan to check this theory by spinning up some of the batts of plain wool that I made from processing my fleeces, and see if I have the same dissonance with those. Either way, this is very good to know.

3) Generally speaking, I want a larger proportion of accent color relative to my base color to really make an interesting yarn. This one is just fine, and I like the way the colors blended into a toned-down semisolid, but in future I think I would use less base color to mix things up a bit. What looks like a lot of accent color on the carder doesn’t look like a lot on the wheel. Again, good to know.

I’ve also spent the past couple of weekends washing my new fleece from Rhinebeck. I do not store dirty fleece for any reason, so when a new fleece comes in there’s always a bit of a push to get it washed up and tucked away. This time I used our new washing machine to do the dirty work, and it was a lot easier than lugging 5 gallon pails. We bought this machine specifically because it was a top-loader with a soak cycle, which is perfect for washing wool, and I knew that that was a feature that I’d like to be able to use in the future.

Unfortunately, it turns out that there is no way to avoid agitation during the soak cycle, so I ended up having to abort that plan and do some more manual manipulation of the settings instead. It worked out ok, though, and the changes meant that I got to use the washer’s allergen setting (30 degree hotter water) to fill the tub, which helped a lot with removing the lanolin.

This was a very clean fleece, but there was still a lot of “sheep” in there, so it took me three soak cycles per batch to get it completely clean. Since it was a huge fleece (7.5 lbs), it took me three batches to wash it all. My office has looked like there was a sheepy explosion over every surface for the past week, but it’s finally dry now, and so I gathered it all up into a pile to put away. I swear there could be a sheep hidden in there somewhere…

That’s a 6′ x 8′ carpet it’s sitting on; this is a lot of fleece.

I still need to go through and sort it for quality; there was a section at the bottom of the bag that was badly sunburned, and has a really bad break in the fiber. (Branden got to experience firsthand what you’re not supposed to hear when you snap a fleece to test it. It’s a dramatic difference.)

Fortunately, I think the damaged section is pretty small, though, so I may be able to trim it down or just comb it carefully to get out those broken tips. It’s also easy to find, since the tips are all sunbleached as well. At worst, I’ll just lose some of the fiber. Most of the fleece is perfect, though. No bits of hay anywhere to be seen, very little suint, and the locks are so open that I could probably get away without any carding at all if I were going for a slightly more rustic yarn.

And finally, I have been working on a swatch. My train knitting has been completely eaten up by work overflow lately, but I’ve managed to steal a few minutes here and there to play with my new Briar Rose yarn.

I’m going for a very simple, knit-purl texture, something cuddly and casual for a sweatshirt-like sweater. Most of the sweaters I’ve knit lately have been very fitted and shaped, almost tailored. This one is going to be plain and simple, and minimally designed to really show off the yarn.

I’m still quite torn about which stitch pattern to use; I kept adding more hoping to find one clear winner, but there are still several options on the table. It turns out that it’s very difficult to photograph the textures in this yarn, but here are the finalists.

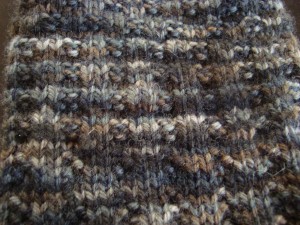

The first is a broken rib:

I really like the depth of texture on this one, and I love how it plays with the color. This was one of the first patterns I tried, and I liked it right away, but somehow my instinct tells me that this is not a ribby sweater. I would love to convince myself otherwise, but my internal auditor is having none of it.

This is the same rib worked with alternating blocks, separated by two rows of stockinette stitch. This had a delightfully pebbled texture in the swatch, and both Branden and I liked it a lot. The fabric was a little stiff, though, and when I washed the swatch all of that 3-D texture stretched right out. If I weren’t already concerned about the fabric stiffness, I’d just go down a needle size, but I think that would make something very rigid, which isn’t what I’m going for.

This next one is a modulation on the idea of a broken rib. I was swatching away on the train, and decided to replace the seed stitch columns in the broken rib with a welted pattern instead (2 rows stockinette, 4 rows purl).

I am unaccountably drawn to this one. If I look at each of the patterns individually, this isn’t my favorite. Branden doesn’t like it much at all. It still has a lot of that ribbed texture, and I already said that I didn’t want a ribby texture. And yet I keep coming back to it. I like the waffle weave texture, and the feel that it gives the fabric. Because the ribs are offset by the welting, the structure isn’t as stiff, and it does interesting things with the texture. It’s certainly not the showiest of the lot, but it’s a strong contestor.

And finally, there’s a more traditional basketweave. This one is 6 rows of k2 p2 rib, separated by two rows of stockinette and offset by two stitches.

This one retained the best visual texture in the washed swatch. The rib sections stayed nice and crisp, but the overall fabric still has pretty good drape. It feels thinner and less cushy than the welted ribbing, but it’s a good, solid fabric that would do the job well.

So those are the four choices. The swatch is still a little damp and I’m waiting for it to fully dry before actually making a decision, but it’s going to be a tough one. Branden votes basketweave (the last one). I’m still stuck on the welted ribs, even though I really can’t say why when I look at it next to the other patterns. Branden says I should just go with my instinct even if I don’t “like” this pattern as much as the others (and yes, he’s probably right). What’s “the blog” vote?

So, there we have it. Three weeks worth of fiber. It’s been a little thin around here lately, but I have a sense that things will pick up again soon. Thanksgiving break isn’t far away, right?