Sat 26 May 2012

The last couple of weeks have been something of a rollercoaster ride around here.

Mostly, my brain has been trying to decide just exactly how I feel about this move, and has been trying on every possible emotion in series, switching at random between one and the next like a two year old playing dress up in her mother’s closet with a stolen tube of lipstick and a pair of mismatched heels.

There are so many things wrapped up in this one little event in our lives.

First, there’s living near my family, which is…complicated. We’re excited to be closer to them again, but then being close also brings troubles of its own. It’s a bit of a tightrope to walk sometimes.

Then, there’s the job. I’ve been oscillating back and forth between insane overwhelm (you should see the completely unrealistic list of things that I plan to accomplish in 7 weeks this summer…hahaha! *insert maniacal laughter here*) and crushing imposter syndrome. The first is pretty normal; I am usually overloaded, and I know how to deal. I feel overwhelmed, but I also know that the important things are going to get done, and are actually progressing really well. That’s really not much of a problem. The second is harder. I don’t often suffer from lack of confidence, so this has been a curious thing to have living in my psyche. It’s been interesting to watch, really, when it’s not busy warring with my self-esteem. It’s kind of like having some wild, exotic animal take up residence in the back yard…a little unexpected, sometimes a little startling, generally just interesting to observe. (My self esteem is robust and is generally winning…no worries there.)

Then there’s the leaving. At first I felt guilty about making Branden move from a job he likes. Right up until he got a new one that he’s super excited about, and that’s closer to what he really wants to do (and that got him better pay to boot). Hard to feel guilty there, except for how he’s leaving a boss and colleagues that he really likes and a company that’s been good to him. But then, I tell myself, that’s business.

Considering how short a time we’ve been in Illinois, we’ve also made a lot of friends here that we’ll be sad to leave when we go. Moving to Massachusetts also puts us that much further away from our friends in Madison, who are many and sorely missed.

I’m also going to miss this house. We didn’t really “click” with the neighborhood, but the house is just about perfect for everything we need. It could use an unfinished basement or a heated garage, perhaps, and a bit more sun in the back yard for a garden, but other than that it really has everything we want in a house. The new one will also be very good, but it is missing a few critical things that are making it hard to be excited about from here (like a pantry, a full-sized refrigerator, and a dye studio). Still, it’s only for a year, and then we’ll move to a better place. Once we’re there, I’m sure I’ll fall in love with it for all of the reasons that we picked it, but lately I’ve been having a hard time seeing past the faults, I think mostly due to a general resistance to the move.

But then there is the ocean! It is hard to overstate how excited I am to be back by the Atlantic. It’s been a long time.

And, I’m excited about getting back into the lab and the classroom, and have lots of interesting things lined up for the summer and next fall (see unrealistic list, above).

In short, I’ve been feeling conflicted. Back and forth, up and down, right side up and sideways. I’ve been doing the only thing you can do in those circumstances; riding it out and moving steadily forward, one box at a time.

My office has been mostly packed for a couple of weeks. The pantry is all but empty, the bedroom is all in cardboard. We’ve sold the things we’re going to sell, thrown out or given away the things we no longer need, and put the rest in boxes. We’re getting down to just the things we need on a day-to-day basis, so we’re getting pretty close. We’ll finish up the odds and ends over the weekend, and then we pack the truck on Tuesday.

In the past few days, I think I’ve finally begun to get used to the idea. Something about saying final goodbyes, stacking all the boxes in the dining room, and planning the drive back East has made it all start to click into place.

On Thursday, I took down the dye studio. Instead of feeling like a loss, it felt like it was time.

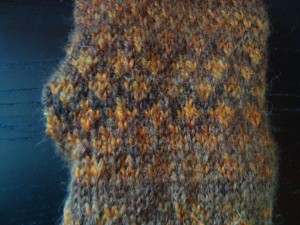

This week, my brain started throwing ideas at me left and right. New knitting designs, twenty different blog posts, a million things to try and do with the website, other hobby ideas, research topics and questions, whole sections of a grant proposal in one fell swoop, and tons of other stuff that I don’t even know how to classify. The rest of my life might be neatly sorted and packed in boxes, but my brain is in a state of delightful chaos. The floodgates are open, and I’ve been writing and list-making and notetaking furiously just to keep up with the deluge.

Now we’re into the final countdown; Branden is around all weekend, so we’ll be finishing up the odds and ends, touching up paint, taking apart furniture, all those little things that have to be done at the end of a move. Were really close to done, and then it’s off to the open road.