Mon 30 Sep 2013

Remember the skirt I was making a few weeks ago?

Well. I started the practice version, and got all the way through the waist finishing when I realized that the fit just wasn’t quite right. It needed some darts in the back. I pulled out the waistband and set about adding some darts for shaping. On the second or third try, I was beginning to remember just how difficult it can be to do final shaping and pinning on yourself. Working with sharp pins behind your own back while twisting to see what you’re doing in a mirror is not always the best way to get results.

I have often contemplated buying a dress form for just such a reason. Unfortunately, they are fairly expensive, and my body doesn’t fit the standard dressform shape anyway (even the adjustable ones leave something to be desired).

A long time ago I heard about people making their own dressforms out of duct tape. It came up again fairly recently in conversation somewhere, and when I got to this particular sticky spot with the skirt it came bubbling right back to the surface. We bought a couple of rolls of duct tape and some expanding foam, and started off on an adventure in 3D sculpting.

I have to say that Branden did most of the work on the dressform. Besides standing very still for an eternally long time to get completely cocooned in duct tape, I didn’t do much at all. Branden fashioned a quasi-skeleton out of cardboard, and then went to work filling the model with expanding foam. We figured that the whole project would take about a week.

A month or so later, it is finally done.

It turns out that expandable foam dries very quickly when it’s exposed to air, but not so quickly when it’s inside a duct tape dress form. We put the first two cans in one at a time, and left them to cure at least overnight. Then we noti can said that it only took 8 hours to cure, so we put the last 3 cans in about 8 hours apart. This turned out to be a mistake. Without the airflow, the foam took weeks to dry and harden into its final shape, and some of it is still slightly soft even now. Remedies included poking holes in the duct tape and other such measures, but did not greatly speed up the process.

Despite a few deformities acquired in the soft-foam stage, the dressform is a very good model of my body (for better or worse…not recommended for those who prefer their mental body image to reality). I have to say that it is a little odd having such an accurate replica of myself standing around in odd corners in the house, but it’s now hiding behind a chair in my office rather than standing eerily around waiting to dry, at least. Those stubborn darts took about 15 minutes to pin and to sew this weekend, and now the skirt is finished. I guess I’d better make more clothes, now that I have a custom dressform!

In other news, the embroidered sweater is off of the needles and blocked as of last night.

It still requires a zipper, which I am afraid will necessitate a field trip to the fabric store, as the zipper I bought last time doesn’t quite match. Â Still, it is inching closer to done, and I do like the way the front rib details came out.

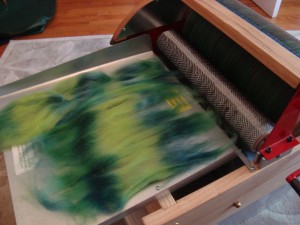

My spinning wheel has also been busy. I took those braids of roving, and sent them through the drum carder:

It seemed like a shame to blend such nice colors, but I want a mostly solid colorway with no dominant color stripes, so blended they must be.

I can’t say that I’m unhappy with the results, either. They’re not as eye-catching as the original braids, perhaps, but I do like the subtle color shifts, too.

Now that they’re blended, the olive also looks like it belongs.

I think I’m going to like this yarn.