I don’t find that I have occasion to complain about the honesty of swatches here very often. I tend to knit at a fairly firm gauge, and I knit large swatches (often 6×12″ or more), so I usually have a pretty good idea of what kind of fabric I’m going to get.

Usually.

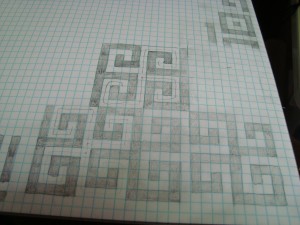

Sadly, the swatch for Branden’s Basketweave sweater is turning out to be one of the unreliable variety.

Does that swatch look shifty to you?

Now, to be fair, I knew as soon as I touched the washed swatch that the knitting was much looser than I usually use for a garment. I like a firm fabric that doesn’t stretch with wear, and I almost always go down a needle size or two from the gauge that most people would use. (Almost without exception, a knitter picking up one of the sweaters I’ve knit will comment on how dense the fabric is.) I’ve been bitten by loose gauge before, and unless the garment really calls for it, I prefer to knit something that I know will stand up to wear and tear without stretching.

For instance, here’s a sweater that I knit for Branden in 2008:

And here’s the same sweater after 6 years of use:

I don’t think it took more than a few months for the sweater to stretch; certainly not more than a few washings. You can see how the fabric at the shoulders has deformed, which makes the drop shoulder far more pronounced (an extra 3-4 inches per sleeve?). Sleeves that were once just a little long now hang an inch or two past his fingertips – and let me tell you, it is hard to make a sleeve that is too long for those arms! Branden still loves this sweater and wears it happily, but I cringe every time I look at it.

Knowing all of this, I decided to stay with the looser gauge on the basketweave sweater, first because I didn’t want the rib/welted fabric to be too stiff, and second because I wasn’t confident that I would have enough yarn to finish in a tighter gauge. (I’m also already a needle size below the low end of the recommended gauge, which says I should get 5-5.5 stitches to the inch on size 4-5 needles. I’m getting 6 sts/in on a size 3, in pattern.) I measured and weighed the swatch, and it suggested that I would be pretty close on yardage, so I went with a bigger needle.

I finished the body of the sweater this week, and started on a sleeve. I had carefully measured my swatch to get a sense of how the fabric would end up, and my stitch and row counts seemed right, but the sweater just took forever to knit. I chalked it up to impatience, and kept on knitting. I finished with a 17.5 inch underseam from the armpit to the hemline, and 28 inches from shoulder to hem. So far, so good.

Then I started knitting on a sleeve, and I started thinking that it would be good to get a really accurate row gauge for the blocked fabric. So, I decided to block the body on the needles. I put it in the sink to soak, and wandered off to do other things. When I came back to squeeze out the fabric, I was surprised at how much give it had. Then I laid it out on the floor to dry.

Allowing the fabric to stretch to its natural size, the sweater was 33 inches from shoulder to hem, and 56″ around the chest (gauge said that it should be just shy of 50″ around). That’s an increase of 20% in length and 12% in width, for those who are counting. The shoulder area appears to be better-stabilized by the raglan shaping and the cables than the body, which is just knit in the round, but there was significant stretching in both areas. A garment designed to fall right below the belt line suddenly turned into a tunic that would hit in the upper thigh.

I scrunched the fabric up a bit to reduce the stretching, and let it dry. It feels bouncy enough, and keeps its shape fairly well now that it’s dry, but even slightly damp it deformed with no trouble at all. Here’s the body post-blocking. Remember, this is the less-stretched version!

(Don’t raglan bodies look funny without their sleeves?)

The sweater now measures about 31Â inches from armpit to hemline; 3 or so inches longer than expected, but not nearly as bad as before. It’s about 48 inches around, so it’s even a little bit on the snug side of the original gauge measurement in width (this makes sense, since stretching longer usually makes fabric pull in and become narrower).

I can easily pull back a few repeats and reknit the ribbing, which will also help with yardage, since the extra length probably uses almost as much yarn as a sleeve, but that leaves the question of whether the fabric will maintain its integrity in the long run.

On the plus side, the basketweave pattern will tend to pull in if possible. That should help to fight stretching out over time. As I said, the yarn is quite bouncy and elastic once dry, and that will probably help to reduce stretching (unlike the Cascade Eco wool used in the other sweater, which doesn’t have much bounce on its own). I could add some crochet seams on the inside of the body to help stabilize the fabric, though they can only do so much.

Or, I could reknit the sweater on a smaller needle and get a better fabric. (That would also give me a chance to redo the color mixing, which isn’t as uniform as I would like.)

I think the sheer weight of the yarn is the reason for my swatch failure. It’s not a terribly dense yarn, but it is heavier than many  on the market. It’s looking like I’ll need to use a full 2.2 lbs in this sweater, which is quite a lot of weight, even for a sweater of this size. The swatch was only about a foot long, so it didn’t have all of the weight of the rest of the garment pulling down on it. It simply wouldn’t have stretched as much. The looser gauge makes it possible for the yarn to shift quite a lot with blocking, and the two factors combined make for some very stretchy fabric.

Of course, that same weight is going to work against me in the wearing of the garment, too; it will tend to put extra strain on the structural elements of the sweater, and will tend to stretch it out of shape over time. The question is whether the elasticity of the yarn and stitch pattern will be enough to counteract the weight and the loose gauge and make a relatively stable fabric. The short answer is that I don’t know.

I’m currently inclined to pull it all back and knit it again on a smaller needle. A few more weeks of knitting time now will be better than several years of watching Branden wear a sweater I don’t like. (And the barrier to ripping back a finished garment is high enough that I’m unlikely to change it once the decision is made, so a wear-now, reknit-later plan won’t work here.)

I’m still concerned about the yardage, and a denser fabric will make for an even heavier sweater than the one I have now. I’m considering ordering a couple more skeins of the yarn: it won’t be the same color lot, but having a couple of extra skeins would help me match the colors better, and it would solve the yardage problem. I’m not sure I want that many leftovers, though, and a 2.5 lb sweater might feel more like chain mail than a comfortable garment!

I’ve spent the past 2 days ignoring the sweater and letting my brain mull over the options while I waited for the body to dry. I don’t want to wait forever to make a decision, so I’m going to have to pick something soon. I’d rather do it right now and end up with a garment that I like, but I’d also rather not reknit the whole thing. (I thought about felting, but that’s a one-shot deal, and there’s no recovery if it fails.)

At least one thing is sure: in the future, I’ll have to remember to be more thorough about interrogating any swatch that looks even a little bit loose and shifty!