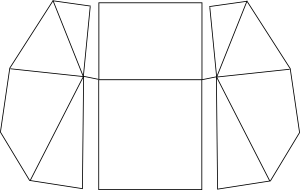

We’re back from Greencastle, and I’m working on sorting through the remaining inventory, things that need to be put away, and the lessons learned from our first fiber festival. If you’re not interested in all the gory details, the show went very well and we learned some useful things, and you might just want to look at the booth photo and scroll on past…the rest is all a blow-by-blow account of what we learned, and may not be terribly interesting.

Still, scientist that I am, I can’t help but feel that this experiment needs a lab report, and it’s something that I really wish I’d been able to find 6 months ago when preparing for this event.

Not many people talk about how they prepare for a show. Maybe it’s because you get used to it after a while and it doesn’t seem like there’s much to figure out. Maybe it’s one of those trade secret things, where you don’t want to give away all the answers. There could be a thousand different reasons, but in the end it boils down to a lot of guesswork when you’re getting started. (From what I’ve heard, the guesswork doesn’t necessarily get better later on, but at least you have a starting place for making your guesses.)

There are so many unknowns at the beginning of this process. What do you really need to bring? How much stock is too much? Enough? Way too little? So, to remind myself of these things for the next show, and to help anyone else out there who might be thinking about trying this out, here’s my first-show breakdown.

First, it’s worthwhile to compare the Greencastle show to others that I have attended (as a customer). The biggest thing I noticed is that there was a lot less traffic than I would have expected. Several vendors there seemed to think that this was a particularly slow year, and said that it was usually well attended. The second thing that surprised me was the size of purchases. Most shows I’ve attended have had at least a few people walking around with big bags full of yarn or fiber for spinning. At Jefferson, the sight of a person walking around with 4 or 5 big bags full of fleece and a manic grin on their face really isn’t at all unusual. At this show, I saw very few people with more than one bag, or even more than a few items. This may be because of our booth placement (more on that in a minute), but it didn’t seem like people were purchasing as much as I have seen at other shows in the past. I don’t know if that’s typical in Greencastle or not, but I think it may be related to my third point, which is that this was almost exclusively a cash-only show. We had put a lot of time into hunting down a way of taking credit card, because I couldn’t imagine not taking card. In all of our purchases, not a single person wanted to use credit/debit; it was all cash and a couple of checks. (I think Branden was a little disappointed that he didn’t get to use his fancy Square card reader after all.)Â Of the two purchases I made, one was on a card and the other was cash because the booth didn’t accept card.

And now for the lessons learned. First, things about the show in general:

1) Location matters. A lot. We were moved at the last minute to a booth behind one of the big barns. The new booth had a roof (instead of the tent we brought) which was really helpful when it rained on Friday afternoon. It was not helpful that we were one of only 4 booths in that area of the show, and that I was the only one selling yarn or fiber in our section. It was also not helpful that they decided to close the barn doors because it was cold, and that most of the traffic passed back and forth between the large indoor areas through the end of the barn opposite to where we were. From our reconnaissance trips to the indoor areas, I would guess that about 25% of the show participants walked past our booth, and probably only 10% saw us in their mad dash for the door to get out of the cold. The people that did see us were usually at the very beginning of their lap through the show, and so weren’t ready to start buying yet. A couple of them did come back around at the end, but most didn’t, as you’d probably expect.

2) Remember about wind. We knew we’d be outside, and that the forecast was for 60 degrees on Friday and mid-50’s on Saturday. We brought warm things, but we forgot to account for how much colder it gets when there is a constant breeze blowing. It would have been useful to have several more layers, though we got by fine as it was. We had plastic sheeting with us, and it might have inspired longer browsing sessions (and certainly would have increased our comfort level) if we’d hung it up as a wind break.

3) Inside is better when the weather is questionable. From what we heard, weather is always questionable at this show. Every vendor there had a horror story about weather at Greencastle, which really isn’t at all surprising for something in mid-April in the upper Midwest. Because it was so cold, the customers spent the entire time inside the barns or dashing back and forth between them. When it was warmer or sunnier, we did pretty reasonable business, but that meant that we only had a few busy hours in the whole weekend.

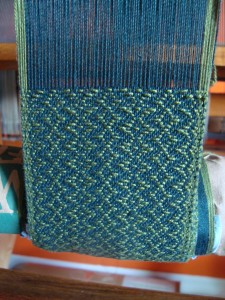

4) Demos help. We had brought lots of samples of yarn spun from my fiber and several sweaters knit from handspun. Being able to talk about how to design a yarn from fiber was really fun, and people liked to be able to touch the skeins. Because of this, we had interest from spinners and non-spinners alike. There was also a really noticeable change in the number of people that noticed our booth when I was actively spinning at my wheel. Unfortunately, my hands were too cold to spin for most of Saturday, but it’s good to know that it’s worth the trouble to bring the wheel, both to keep me amused and to draw people in.

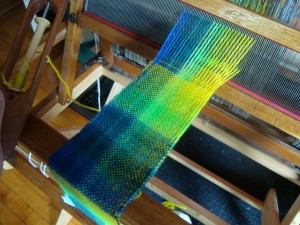

5) Our presentation is good. Several people commented that they liked the braids as a way of packaging the fiber. A couple of people wanted to buy our fiber stand right out from underneath us. We didn’t spend much on display because this was our first show, so it was gratifying to hear that we’d done well with what we had. Our booth was small, but at least it didn’t scream amateur.

6) We brought the right amount of stock. This was my biggest obsession up to and during the show, and it’s the one that’s just impossible to predict. How much is enough? Both Branden and I were feeling a little sick at the beginning of the show, watching all the pros bringing in hundreds of pounds of stock. What if we were totally wiped out in the first day? How do you manage inventory to make sure you have enough to offer choice throughout the show, but still make sure you’re not holding back what you could be selling? It turns out that we needn’t have worried. We brought 144 braids of fiber, and sold 7 in the first hour and a half (before noon). After that, we sold 2 more before the end of the day (7 pm) on Friday. We sold nothing on Saturday morning (very cold and windy), but the afternoon was busier, and we had a couple of people take us up on the buy 4 get 1 free promotion, so our total was up to 26 braids sold by the end of the show. Just before closing, we made a wholesale sale of 33 more. We had enough stock to offer choice throughout the show, and we would have had enough to accommodate a busier marketplace. I think it’s unlikely that we would have sold out, even in a prime location in a busy show, which means that we probably had roughly the right amount on hand.

Now, things I learned about the market:

1) There are not all that many spinners. Many people stopped by to look, and almost all were interested in spinning, but there weren’t many who actually spin. There were lots in the “well, I have a wheel….” category, and a few in the “planning to learn soon” category, but not many that self-identified as spinners. Clearly, spinners need to work on PR.

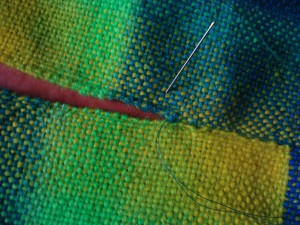

2) People loved the colors. Above all, that was what drew them into the booth. Even non-spinners were interested in stopping by to look at my colors. I take this to be a very good sign.

3) My yarn base needs to be improved if I’m going to offer yarn. Lots of people loved the colors in my skeins, but we didn’t sell any of the small selection of yarn I had on hand. I think it’s just not an exciting enough yarn base. I’m not particularly inclined to explore this area further, but it’s worth knowing that the yarn base I’ve used in the past isn’t terribly compelling.

4) Buying selection was based on color, not fiber. Very few people cared much about the breed of fiber that they spun; most were drawn in by a particular color and went with that. A few people cared about the breed properties or wanted to spin something new, but for most that was a secondary consideration.

5) Most people buy without a project in mind. Maybe this is in the “duh” category, but it surprises me. Only a couple of people actually had any plans for what they would do with the yarn that they spun; it’s just not a factor in the buying decision. (This is completely opposite of my tendencies, so it’s an especially important thing for me to keep in mind.)

6) Quantity doesn’t matter. A couple of people asked if we had larger quantities of a particular color. No one seemed inclined to match/combine colors for a project. Even the people who bought larger numbers of braids bought them as individual units, not as part of a larger collection. I personally don’t really buy or spin 4 oz quantities, because I am always working on a larger project and 4 oz is never enough, so it surprised me that no one wanted larger amounts. (I suppose I should see #5 above.)

7) Multicolor braids sold better than semisolids or single-color gradients. A large portion of my stock was semisolid or single-color, because it’s so easy to spin them into a yarn that I find knittable, and they are easy to use to complement a wilder colorway. Combining #s 5 and 6 above, it’s not surprising that this appeared to make no difference. Multicolor sells better, and high-contrast multicolor was best of all. Good to know.

8 ) I missed the story line. This is more about me than the market, but I really missed being able to point to a photo or an inspiration and be able to explain where a colorway comes from. That’s the part I really like about selling through the blog, and it was definitely missing in the show environment. I will need to find a way to include this in the future.

That’s a lot of lessons! There are even more on my list, but I think that those are the biggest ones. A lot of them are things that you can only learn by getting out there and trying it, so I think the show was worthwhile. Our sales weren’t stellar, but they were sufficient, and the feedback was very good. We had good conversations with a few people, and I’m hopeful that there will be some new voices on the blog as a result (if this post doesn’t scare everyone off). The wholesale order also means that my fibers will be making their way to Maryland Sheep and Wool, so we’ll get some more exposure there. On the whole, I think we can call this a success.