Branden and I spent last weekend learning how to silk screen.

The “why” is kind of a long story, but it has to do with a new, non-knitting project that’s been going on in the background lately. It all started a few months ago when Johnny* (a blog writer I follow) was bored and felt that things needed some shaking up.

*Warning: Johnny likes to swear. That’s not the tone of my site, so I want to give fair warning before you go clicking over there and being shocked. Photos to follow also include edgier language than you usually see here. If at work or otherwise in public, consider yourself forewarned.

So, Johnny had a project in mind to get things moving. He’s generally in the business of inspiring people to set out on their own and create their dream business, and runs into a lot of “I would, but…” kind of excuses. He’s also run into some people doing incredible things despite the odds. There’s Jon Morrow who became a real estate tycoon, despite the fact that he’s in a wheelchair and can’t even enter most of the houses he buys and sells. There’s Warren McDonald who climbs mountains despite the fact that he lost both his legs in a climbing accident, and there are lots of others. I’ll bet you’ve even met a few of these people, the kind that Johnny calls “badasses.”

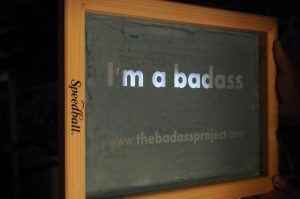

So the question is, if they can do it, why can’t the rest of us? Just think of how much the able-bodied world has to learn from those who have seen life’s challenges and then raised the bar. He wanted to get their stories told, both to honor them and to inspire the rest of us to get out of our own way and just do the things we’ve been dreaming of. And so, the Badass Project was born. (Johnny explains the project in full on his blog, if you’re interested.)

Honoring and enabling excellence is something I believe in. I’ve known a few badasses of my own, and I am excited to help bring their stories to light. So I stood up, and I got involved.

You’ve probably been around long enough to know that “I got involved” is often a bit of an understatement for me. I’m now officially running the fundraising effort for the first year of the project, among other things.

One of my various jobs is the task of obtaining t-shirts and other merchandise for the project. I’ve been poking around online, noticing how expensive it is to get t-shirts printed (did you know it costs $5 more per shirt if you want black instead of white??). We have ambitious fundraising goals, but nothing’s in the bank yet, so that first run of orders for a hundred t-shirts is a bit steep to start out.

And then, last week, I ran across this post, and my brain went “click.”

Clearly, the solution is to learn a new craft.

We bought some silk screening supplies, and spent Saturday morning coating the screens with a light-sensitive paint, which we then cured under a very bright light. We had printed text for the shirts on overhead transparencies, and laid these over the screens while they cured. After a few minutes, we washed out the undeveloped paint, and we had a silk screen:

Then, we taped up any areas we didn’t want to print right away

and filled the rest with fabric paint.

Then, we washed out the screens, retaped them, and applied the second color.

And finished the printing

We have a long way to go to get to expert, and we need both a coarser-weave screen and some alignment tools before we’re in business, but we’ve learned the basics, and we had a really good time.

I don’t know if we’ll actually end up making the final set of shirts, but it was fun to learn a new skill. I’m not sure yet exactly what will come of this collision of crafting with the non-crafty areas of my life, but I can see all kinds of ways that this could come in handy.

And even if it doesn’t, at least I know how to silk screen.